TPS Consulting: The Key to Optimizing Business Process

Performances

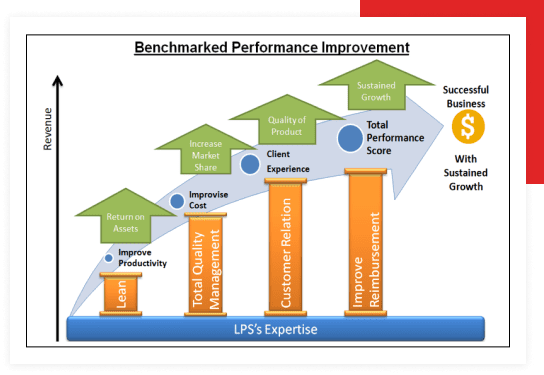

Our energetic and skilled consultants have completed more than 4,000 customer projects. The improvements can be classified as follows, along with the achieved performance.